World’s first liquid air engine operational on schedule

A revolutionary new zero-emission engine could save truck operators thousands of Euro in fuel costs and the environment millions of tonnes in emissions through new cool chain systems for food distribution and in motive power applications.

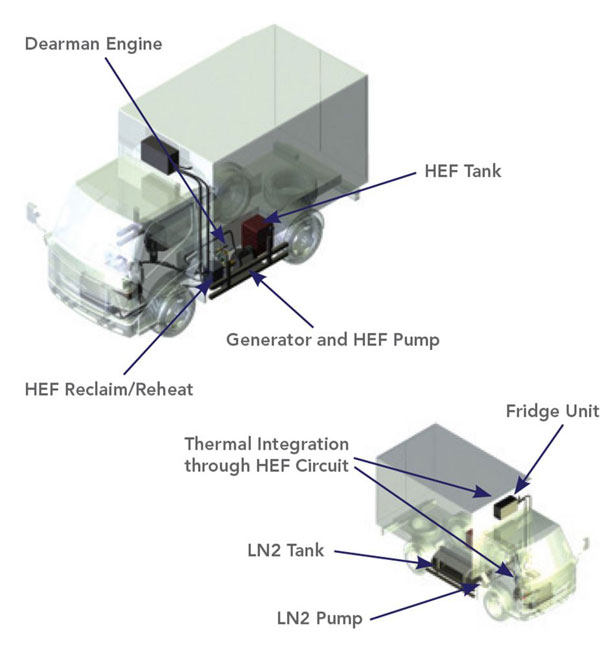

The Dearman engine, which has been developed in the UK, runs on liquid air (liquid nitrogen) and is on track to undertake full on-vehicle testing by the summer of 2014. The engine, designed to provide both the power and cooling for refrigerated trailer applications, could be in production within two years and, with a network of industrial gas plants across the UK already producing liquid nitrogen, there is no infrastructure barrier to rapid deployment.

The Dearman liquid air engine – an innovative heat engine that uses liquid air as a ‘fuel’ – completed its ‘shakedown’ testing milestone at the end of 2013 and has entered a three-month programme of tests and performance mapping. The developers, Dearman Engine Company, confirm that the engine remains on track for integration and installation on a vehicle by MIRA (Motor Industry Research Association) in the first half of this year.

The project – in partnership with MIRA, Air Products and Loughborough University and jointly funded by the consortium partners and the UK Government (IDP8) – will demonstrate and test the Dearman Engine on a refrigerated truck providing zero-emission cooling and power during 2014, before moving to full on-road field trials.

MIRA’s Commercial Manager for Future Transport Technologies and Intelligent Mobility, Chris Reeves said: “MIRA is proud to lead a project delivering the world’s first demonstration of a liquid air engine in a commercial vehicle. Liquid air is an exciting new energy vector and has the potential to make a major contribution to the low carbon challenge facing the transport sector.”

The rapid growth in recent years of small format convenience stores and home delivery, which require smaller and more frequent deliveries, is changing typical vehicle duty cycles. Fast trailer temperature pulldown – a key feature of the Dearman engine – is becoming increasingly important as delivery schedules continue to increase the number of daily door openings. Additionally, with 20% of a refrigerated truck’s fuel spent on cooling, the Dearman engine offers thousands of pounds in lifetime fuel cost savings.

With many of these stores situated in urban areas, the Dearman engine also offers massive local air quality improvements since it exhausts only clean, cool air and no harmful NOx (nitrous oxides) or PM (particulate matter).. The unique design of the Dearman engine also raises the prospect of quiet nighttime deliveries – a significant logistical advantage.

Cryogenic refrigeration systems are not new to the industry – up to 1000 are in use across Europe; showing interest in a refrigeration workhorse that is quiet, emits no local air pollution and cuts an organisation’s CO2 emissions. The Dearman engine is a significant improvement over existing liquid nitrogen evaporation systems, since not only does it use the cold directly from the liquid nitrogen to cool the trailer, but it also uses the pressure created by the expansion of liquid nitrogen to drive a piston and produce power. This power is then used to run a downsized refrigeration cycle for free – resulting in savings of almost £3000 a year against liquid nitrogen refrigeration. Even against diesel, there is a saving of up to £1500 a year. The Dearman system does not spray liquid nitrogen into the trailer, therefore dispensing with the need for expensive safety systems to ensure operator protection.

‘Liquid air’ as a new zero-emission energy vector sprang to national prominence in May 2013 with a ground-breaking report from the Centre for Low Carbon Futures (CLCF) entitled Liquid air in the energy and transport systems: Opportunities for industry and innovation in the UK. The CLCF report found that liquid air could reduce diesel consumption in buses or freight vehicles by 25% using a liquid air / diesel hybrid, while using a liquid air engine would cut emissions from refrigeration on food lorries by 80%. The report also raised the possibility of zero-emission liquid air city cars filling up at road-side forecourts at a fraction of current fuel costs and with lower lifecycle vehicle emissions than either electric or hydrogen powered vehicles.

The adoption of liquid air technologies in heavy-duty vehicles could also reduce the UK’s diesel consumption by 1.3 billion litres and its carbon emissions by over a million tonnes by 2025. It could also reduce local air pollution dramatically: introducing liquid air trailer refrigeration alone would cut emissions of carcinogenic particulate matter by 180 tonnes per year, equivalent to taking 367,000 modern diesel lorries off the road.

These are some of the preliminary findings of Liquid air on the commercial highway, a major new report from the Liquid Air Energy Network (LAEN), Centre for Low Carbon Futures (CLCF) and University of Birmingham, to be published June.

The concept for this technology also includes a diesel hybrid application. By harnessing the low grade waste heat of the ICE cooling loop, the Dearman engine can deliver 25%+ reduction in fuel consumption for a diesel heavy duty engine. The ability to work alongside other waste heat recovery systems is an additional advantage. Further development work is underway in this area.